Exploring Everyday Plastic-free Alternatives

Eco Essentials

Cork Laptop Bag

Cork Laptop Bag : Our compact and lightweight VEGAN CORK LEATHER laptop bag is perfect for those on the go.

It has ample space, to easily accommodate a 15" laptop. With enough internal pockets/segments and reinforced sides to protect your documents and laptop, this practical bag is perfect for the style conscious prof... Read More

Bhoomi Beach Yogi XL Cork Eco Yoga Mat

Regular Price: ₹4,499

Special Price: ₹3,750

Bhoomi Beach Yogi XL Cork Eco Yoga Mat : This cork and natural rubber eco yoga mat captures the energy of the ocean with its design that is both soothing and refreshing. The extra width gives you more space for your practice. The top surface of XL Beach Yogi mat features a symphonic blend of two sustainable materials: cork and r... Read More

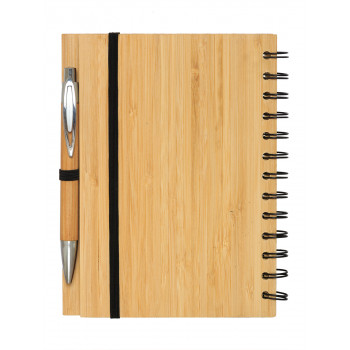

Bamboo Notepad with Pen

ECO-FRIENDLY MINI NOTEPAD

This beautiful notebook is made of 100% recycled paper, as you can see from the distinctive yellowish colour of its pages. This eco-friendly notebook has 70 lined pages and along with the pen it comes with, it is just great for all purposes!

Sheet Size: A5

P... Read More

Sirona Biodegradable Super Soft Black Sanitary Pads/Napkins, Antibacterial, Ultra Thin and Rash Free Protection - Small (S) Day Pads (Pack of 10)

Sirona Biodegradable Super Soft Black Sanitary Pads/Napkins, Antibacterial, Ultra Thin and Rash Free Protection - Small (S) Day Pads (Pack of 10) :

How am I made?

Carbon is captured from sustainable natural resources, such as Corn, Sugarcane, Cassava & Straw Bale, & transformed into PLA usin... Read More

EcoBuddy Cotton Vegetable/Fruit Bag, (Pack of 5)

EcoBuddy Cotton Vegetable/Fruit Bag, (Pack of 5) : EcoBuddy cotton vegetable & fruit bags are best for your vegetable and fruit shopping needs. They are reusable and will last for many years. Feel proud about the way you shop sustainably! The idea was to make the best alternative for the daily use of plastic bags, by choosin... Read More

Garbage Bag 15 Pulls (19*21)

Garbage Bag 15 Pulls (19*21) :

Maintain cleanliness and hygiene in your home & office with Imvelo "DISPOSE SAFE" Compostable Garbage Bags. An alternative to toxic plastic bags, Imvelo Garbage Bags are a practical and green solution for waste disposal.

Plantable Seed Pencils - (Pack of 50)

Pepaa Eco-friendly Plantable Seed Pencils are made using Pepaa proprietary pencil design – we are one of the world’s first seed pencils brand that makes plantable pencils from recycled paper.

We may have seen Plantable pencils before. That however is made from wood. It doesn’t make sense to cut down trees and then have ... Read More

Dual Bristle Neem Wood Comb + Pocket neem wood comb

Regular Price: ₹230

Special Price: ₹207

Dual Bristle Neem Wood Comb + Pocket neem wood comb : Vruksh Neem Wood Combs are of premium quality and are made of wood which is available from neem tree. It consists of anti fungal and anti microbial as it's primary component is neem wood which has medicinal benefits. It is non static which leads to less hair fall and als... Read More

Coconut Fiber- Coir Scrub & Laundry Brush

Coconut Fiber- Coir Scrub & Laundry Brush : A simple coconut waste can make for natural cleaning alternatives. The pack of Coir scrub and Multi-purpose Brush keeps filth at the bay. Its made from Coconut Coir which makes it completely biodegradable. Like synthetic scrubs, these don’t smell or become moldy as Cocon... Read More

Origami Good Karma Toilet Roll - Pack of 4

Origami Good Karma Toilet Roll - Pack of 4 : The Good Karma toilet rolls are 100% recycled, including the packaging. Our 4-in-1 rolls are 3 ply and the number of usable sheets is 260 sheets per roll. The toilet rolls are extremely safe for your supple skin and are cured at above 120*C to ensure hygiene! They do not clog dra... Read More

Trending

Mini Wireless Bamboo Keyboard with 2.4GHz USB

This is a Mini Wireless Bamboo Keyboard with 2.4GHz USB

Compact, easy to use with sweat absorbent properties. Looks and feels better as it grows old with you. All natural bamboo body and texture. An electronic device for the bamboo enthusiasts!

Features:

- Interface Type: USB Read More Add to Cart

Set of 4 Bamboo Kids Drinking Cups, Stackable & Reusable - Sunset

Set of 4 Bamboo Kids Drinking Cups, Stackable & Reusable - Sunset:Range of Modern and stylish Bamboo Kids Drinking Cups, Stackable & Reusable - minimalistic, non-toxic and BPA – free dinnerware for kids. All our products are food – safe and comply with all standards and regulations (Approved by FDA & LFGB... Read More

Add to Cart

Automatic Day Night Light Sensor Switch

Regular Price: ₹715

Special Price: ₹599

This Automatic Day Night Light Sensor Switch can switch on any Electrical device automatically when Dark falls and switch off in the morning automatically.

Just install this smart LDR - Dusk to Dawn sensor Twilight switch at your home, office, Warehouse, Factory or Farm and watch your electricity bills cut down.

... Read More

Add to CartBhumi - Terracotta Clay Water bottle - 1L

Bhumi - Terracotta Clay Water bottle (1000ml): The terracotta clay water bottle is crafted to inspire a healthier lifestyle, reviving the traditional use of earthenware, designed with a contemporary outlook. Made from clay, its porous nature keeps the water naturally cool all day without any refrigeration. An alternative to plas... Read More

Add to Cart

Earthenware Black Stone Kettle & Longpi Tea Cups (Set of 4 cups + 1 kettle)

Amaze your guests with this ravishing Set of Earthenware Black Stone Kettle & Longpi Tea Cups. Handcrafted with a mixture of black Serpentinite stone, clay and weathered rock. Also known as Manipur Pottery, Black Pottery or Longpi, they are believed to make tea of coffee taste better retaining the natural essence of the contents... Read More

Add to Cart

pCure Toilet Rim Block

TOILET RIM BLOCK - pCure toilet rim block is a small and easy to use unit that you place in your toilet. It has colour and pleasant fragrance. This poduct is made in Sweden.

- Developed for the regular Household : Especially developed to take care of broad range of pharmaceutical residu... Read More Add to Cart

Murgi & Eggs With Cups

Murgi & Eggs With Cups is a wooden toy containing 5 brightly coloured eggs with cups, each with a number and dots respectively. It also has 5 coloured tablets with chicks printed on them. It is a set of two games that allow children to match numbers and colours. One game is based on quantity vs symbol-recognition and the oth... Read More

Add to Cart

POST Tote type 2WAY backpack Regular / anello

POST Tote type 2WAY backpack Regular / anello :

A 2-way backpack that can also be used as a tote bag has been added to the series, which is entirely made of heathered polyester canvas that creates a unique texture! The backpack strap is retractable and can be carried neatly as a tote. A great feature is the convenient si... Read More

Add to Cart

RETRO clasp backpack (Regular) / anello

RETRO clasp backpack (Regular) / anello :

The material on the back of the shoulder and the back of the backpack will be changed to nylon material.

The design is soft and smooth to the touch and has an attractive retro feel.

The opening ha... Read More

Add to Cart

Group Activity Game - Fish Pond

Fish Pond is a group activity game where children catch and collect fish of the same colour as on their fishing rod. It challenges the skills of the child with their hand-eye coordination and colour matching making it both engaging and competitive. This toy also helps in pattern recognition as children emulate the given set of f... Read More

Add to Cart

Easy Being Green

Regular Price: ₹37,670

Special Price: ₹30,136

ROSIE TENCEL PINK PANTS AND ROSIE LOOSE FIT LONG SHIRT SET

ROSIE TENCEL PINK PANTS AND ROSIE LOOSE FIT LONG SHIRT SET :

With our Rosie Pink Pants, add a pop of colour to your boss lady ensemble. With precise lines and a natural rise that sits just right at your belly button, these pants are high, but not too high. The silhouettes on these pants are done keeping in mind every lit... Read More

Add to Cart

Cork Wallet Unisex

Cork Wallet Unisex : Say hello to our multipurpose unisex VEGAN CORK wallet. You can practically store all cards, passports, cash when you are on the go. This premium looking cork wallet is not only lightweight but also is light on our heart as they are completely cruelty free and chemical free too. It is water resistant, w... Read More

Add to Cart

De'Dzines Handcrafted Eco-Friendly Comfort Pool Chair & Low Coffee Table Furniture Set for Living Room / Garden / Patio / Terrace / Bar / Pool Side (Set of 4+1) Indoor / Outdoor

Regular Price: ₹37,670

Special Price: ₹30,136

4 Comfort Pool Chair and 1 Coffee Table :

- Highly durable, rust proof, water proof, weather proof, termite proof, low maintenance and very comfortable

- Chair dimension (l x b x h): 66x66x60 cm,

- table dimension (l x b x h): 63x63x46 cm

- Eco- friendly furniture, reusing rubber ... Read More Add to Cart

Space Galaxy 100% Cotton Antimicrobial Kids Yellow Bedsheet Set

Space Galaxy 100% Cotton Antimicrobial Kids Yellow Bedsheet Set

Create into sustainable spaces with SWAAS 247. Experience the comfort of eco-friendliness with our home and lifestyle staples. Sustainably made with 100% fair trade cotton , our Floral Passion bedsheet is sure to help you transform your home into a cheerful... Read More

Add to Cart

Klassic | Black+blue - go-to wallet and card holder

Klassic | Black+blue - go-to wallet and card holder : Klassic is what the name suggests. It’s your go-to wallet and card holder. 100% plant-based, the acorn material with cotton black lining is the proper definition of charm. It’s different in everything: the looks, the function, the build, and the material. Mad... Read More

Add to Cart

Round Sling Bag/Clutch With Changeable Sleeve (Solid Black & Floral Creeper Red)

Round Sling Bag/Clutch With Changeable Sleeve (Solid Black & Floral Creeper Red):

Smart, chic and eco-friendly with adorably minimalistic in style - the Lukka Chuppi Round Clutch is the perfect companion of the modern fashionista.

Flaunt your uniqueness while being in vogue with a nature -friendly compo... Read More

Add to Cart

Mini Wireless Bamboo Keyboard with 2.4GHz USB

This is a Mini Wireless Bamboo Keyboard with 2.4GHz USB

Compact, easy to use with sweat absorbent properties. Looks and feels better as it grows old with you. All natural bamboo body and texture. An electronic device for the bamboo enthusiasts!

Features:

- Interface Type: USB Read More Add to Cart

Suit up Laptop Sleeve

Suit up Laptop Sleeve : The materials used to create this Felt Laptop Sleeve offer superior strength and a soft hand feel. This durable and lightweight Felt Laptop Sleeve protects your favorite device from scratches, dints, dust and spills, scrapes and allow for easy transport. This stylish and soft Laptop Sleeve has been sewn i... Read More

Add to Cart

Madake Bamboo Bath Towel-Vacation Blue

Madake Bamboo Bath Towel-Vacation Blue :

Features:

- Compact

- Quick dry

- Luster look – its subtle sheen steals your heart away!

- Very soft on the skin. Don’t be fooled by its soft texture! Its super absorbent!

- Comfort: The towels are really s... Read More Add to Cart

Roll down laptop bag

Roll down laptop bag:This expandable laptop bag is made from upcycled tyre tubes and vegan leather. The design and material is such that it is water resistant and long lasting. Designed for today's mobile lifestyle with new materials, updated construction and superior protection. Minimalist look with a smooth, minimal panel desi... Read More

Add to Cart

PLASTIC FREE ALTERNATIVES

Coconut Fiber- Coir Scrub & Laundry Brush

Coconut Fiber- Coir Scrub & Laundry Brush : A simple coconut waste can make for natural cleaning alternatives. The pack of Coir scrub and Multi-purpose Brush keeps filth at the bay. Its made from Coconut Coir which makes it completely biodegradable. Like synthetic scrubs, these don’t smell or become moldy as Cocon... Read More

Add to Cart

Set of 4 Bamboo Kids Drinking Cups, Stackable & Reusable - Sunset

Set of 4 Bamboo Kids Drinking Cups, Stackable & Reusable - Sunset:Range of Modern and stylish Bamboo Kids Drinking Cups, Stackable & Reusable - minimalistic, non-toxic and BPA – free dinnerware for kids. All our products are food – safe and comply with all standards and regulations (Approved by FDA & LFGB... Read More

Add to Cart

Travel Eco-friendly Zero-plastic Starter Kit

A PERFECT GIFT TO HELP DECREASE PLASTIC

Everyday items that you would otherwise use plastic – These are all sustainable alternatives. And helps reduce more than 1100 pieces of plastic per person per year.

Starter Kit contains Cutlery Kit (5 Items) :

- 1)Bamboo Spoon ... Read More Add to Cart

Perfect Eco-Friendly Disposable Party Pack (All in one)

Perfect Eco-Friendly Disposable Party Pack : Ideal for every elegant and happening party! This eco party pack is perfect for 10 people get-togethers and is 100% biodegradable from product to packaging!

This party pack contains 10 units each of Dinner plates (10 inches), Quarter plates (6 inches), Spoons... Read More

Add to Cart

BLACK BERRY WOODEN COPPER BOTTLE

THE WOODEN COPPER BOTTLE : Blackberry wood :It has been proven that drinking water from plastic bottles can lead to serious ailments in the long run. Switching to other natural materials is the way to go for better wellbeing.

Our bottle Sangam is a fusion of the 2 beautiful elements of nature the metal copper and earthy ... Read More

Add to Cart

Koko Boho Bowl

Koko Boho Bowl : Add a little bit of the beach vibe to your meal simply by having them in KokoBowls and be an environmental hero for the day? Everyday?

Kokobowls are sturdy and lightweight bowls made from reclaimed coconut shells. The shells are sorted by shape and size to be smoothened by our craftsmen and sh... Read More

Add to Cart

Reusable beeswax food wraps - Full Kitchen variant (3pc-S,M,L) - Ivory White

Regular Price: ₹540

Special Price: ₹499

Reusable beeswax food wraps : Reusable, sustainable, all natural and handmade.

Completely natural, biogeradable and reusable for 8-10 months.Food wraps can be used to seal, pack, carry or store any dry storage, cut fruits,left over food bowl covers or sandwiches, rolls and so on.It sticks with the warmth of your han... Read More

Add to Cart

The Set of Organisers (Rectangle) - Blue Stripes (S,M & L)

The Set of Organisers (Rectangle) - Blue Stripes (S,M & L)

This Blue Striped rectangle box is a secret stash for clean and organized living. Be it lingerie, ties, socks or office files and stationery, these boxes are a great way to organise anything and everything.

We believe that when we have less mess, we h... Read More

Add to Cart

Stonesoup Petals - Mandya Pads (set of 3 Cloth Panty Liners)

Stonesoup Petals - Mandya Pads (set of 3 Cloth Panty Liners) :

Mandya Pads are soft, hypo-allergenic, washable panty liners that can be used for spotting, mild incontinence, vaginal discharge or on those 'expecting my period' days. They are compact to carry (can be folded to fit into a purse or a pocket), easy-to-maintai... Read More

Add to Cart

The Stationery Organiser - Rollover for Stationery and Essentials.

The Stationery Organiser - Rollover for Stationery and Essentials: This roller is designed for easy and fast access,preventing the task of digging for minutes into your heavily filled pouches. It keeps your stationery organised helping you understand and carry what is neccessary and stay decluttered. The siz... Read More

Add to Cart